NEWS CENTER

NEWS CENTER

Drum type axle is also called drum brake bridge, and its braking mode is drum brake. Drum brake has been available for nearly 100 years, but it is still widely used in freight vehicles. Drum axle is also the type of axle with the highest proportion in the commercial axle Market at present, and it is widely installed on some semi trailers, trailers or trucks.

Composition of drum axle

Drum axle is mainly composed of shaft assembly, brake assembly, wheel end assembly, camshaft assembly, etc.

Braking principle of drum axle

Compared with the disc axle, the most obvious feature of the drum axle is the 360 ° closed brake drum at both ends of the axle beam.

When the vehicle is running, the brake drum rotates with the wheels, and a static brake pad is set in the brake drum. When the vehicle needs to be braked, the brake pad is pushed outward under the action of the piston, grabbing the inner wall of the brake drum and generating friction, so as to achieve the braking effect.

Advantages of drum axle

1. Large braking force: the friction area between the brake pad and the brake drum of the drum axle is large, and the friction force generated is sufficient. Therefore, the drum axle outputs large braking force, which is especially suitable for freight vehicles with relatively large weight.

2. Low production cost: drum brake technology came out earlier, and has been applied in vehicle braking for a long time. The technology is more popular, and the technical level of the manufacturer is relatively low. Therefore, the cost input is less than that of disc brake.

3. Convenient maintenance and replacement: at present, the models and specifications of most drum brake bridges in the market are uniform, with strong versatility. It is relatively convenient to replace or repair later.

Disadvantages of drum axle:

1. Obvious heat decay: Although the brake drum surrounding the seal provides stronger braking force, it also causes certain difficulties in heat dissipation of the brake system. Especially under the condition of continuous braking, the brake pad is prone to heat decay due to overheating, which affects the braking effect. Therefore, try not to step on the brake continuously for a long time. If the road conditions require, take cooling measures or use auxiliary braking devices to avoid thermal attenuation of the braking system.

2. The brake drum is easy to store water: after the drum axle wades, the brake drum is easy to enter water, which will reduce the friction output between the brake pad and the brake drum to a certain extent and form water attenuation. Therefore, after the vehicle is waded or washed, it is better to step on the brakes continuously to consume the water in the brake drum and test the braking performance.

3. Brake response is relatively slow: the brake linkage of drum type axle is more complicated than that of disc type axle. The brake response is relatively slow, and the force of stepping on the brake is not easy to control, which is not conducive to high-frequency braking.

4. Daily maintenance is indispensable: it is also because of the complexity of the drum brake structure and the large number of parts and components. The car owner needs regular maintenance, especially the adjustment of the brake clearance, and should not take it lightly.

Application fields of drum axle:

Although the drum axle is not as good as the disc axle in terms of braking stability, the drum axle still has the irreplaceable advantages of disc brake for those vehicles with large cargo weight and large loading capacity, such as vehicles transporting sand, stone, steel coil, wood, coal and other goods.

In addition, the drum bridge is applicable to a wide range of transportation, except for those with high requirements for cargo damage, most general cargo transportation can be applicable.

It is undeniable that the drum axle of the same tonnage is much cheaper than the disc axle, which is more acceptable to most car owners. Especially in the current environment of low freight and rising oil prices, it is almost the consensus of car owners to reduce the cost of comprehensive vehicles.

Common specifications of drum axle:

Common faults and troubleshooting of drum axle:

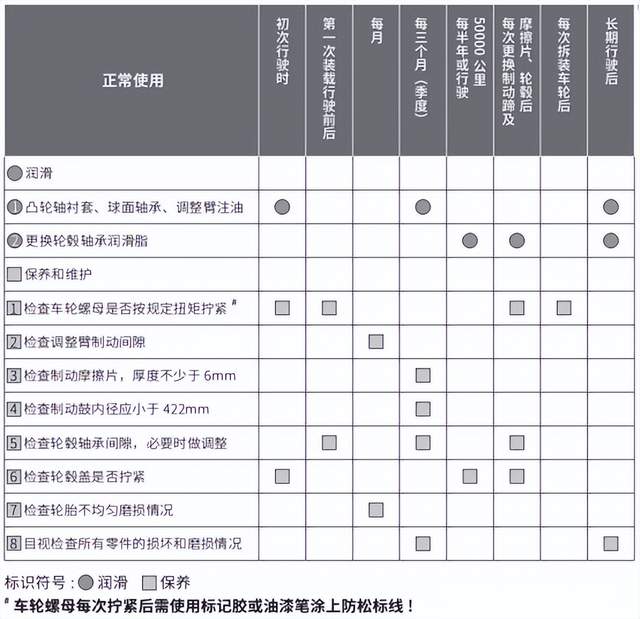

Suggestions for maintenance frequency of drum axle:

Drum axle selection Darong:

1. The raw material is 20Mn2 high-strength alloy seamless steel pipe produced by Tianjin "seamless". The wall thickness is 10-11mm. The tensile strength, yield strength, impact toughness and other properties are better. The strength, toughness, ductility and fatigue resistance of the axle are better.

2. There is a special high-standard factory, and the whole production process is subject to unified and strict quality control. There are 15 production processes, which fully meet the requirements of the national standard.

3. The quality inspection procedure covers every link of design, production and testing. At the same time, quality inspection workshops such as fatigue test, salt spray test and magnetic particle flaw detection test of shaft body are set up, and high-precision instruments are equipped to accurately test the stress limit of the axle to ensure that fatigue failure does not occur during the service period.

4. Select the parts suppliers who have been deeply engaged in the industry for many years, such as Luoyang bearing, Huateng heavy industry hub, Feiying brake pad, Mobil grease, etc. the quality has been tested and tested by the market, and the quality assurance ability is reliable.

5. The axles, axles and accessories of Darong group are equipped with warranty service commitment, and a special after-sales team is established to track the use of users and help customers solve product related problems. Darong automobile bridge has entered the market for 20 years, and its cooperative customers are all over the world, always maintaining zero quality disputes.

6. Axle customization service: design drawings and carry out customized production according to customers' actual use needs, meet customers' requirements for different tonnage, wheel track, parameters, etc., and provide diversified parts matching schemes, so that customers can feel more comfortable.

ONLINE MESSAGE

24-hour consultation telephone

24-hour consultation telephone

400-6363-989

If you have any needs, you can contact us

CONTACT US

Customer Service Hotline:400-6363-989 Company Address:No. 2, Guoyuan Road, Industrial Park, Quanpu Town, Liangshan County, Jining Cityall rights reserved Darong traffic machinery Co., LTD Lu ICP No. 20025388-2